Gründung Abteilung Speed Badminton

Gründungsdatum ist der 11.01.20213

Die Abteilung „Speed Badminton“ des TSV Poing wurde am 11.01.2013 gegründet und erfreut sich seither eines regen Mitgliederwachstums. Aus Speed Badminton wurde ab dem 1.1.2016 das heutige Crossminton.

Bereits kurz nach unserer Gründung haben wir an den Wettkämpfen der 1. Speed Badminton Bundesliga Süd mit erst einer, dann zwei Mannschaften pro Saison teilgenommen.

Darüber hinaus sind diverse unserer Mitglieder auch auf nationalen und internationalen Turnieren, sowie allen Meisterschaften (von der deutschen Meisterschaft bis hin zur Weltmeisterschaft) unterwegs.

Alles in allem konnten wir bereits so manche sportliche Erfolge erzielen. In unseren Reihen befinden sich mittlerweile eine Vizeweltmeisterin und vier deutsche Meisterinnen sowie zahlreiche nationale und internationale Champions!

Abteilungsleitung:

Stellvertretende Abteilungsleitung

Beisitzer 1, Sportliche Leitung

Beisitzer 2, Öffentlichkeitsarbeit & Presse

Beisitzer 3, Sponsoring, Trikots und Werbemittel

Spiel‘ wo Du willst: in der Halle, in Parks, am Strand – ohne Netz, einfach loslegen und Spaß haben. Deiner Phantasie sind keine Grenzen gesetzt. Vergiss Federball! Die Speeder®fliegen zielgenau und das sogar bei Wind. Ob bei Tag oder Nacht, Fun- oder Matchspeeden kannst Du immer.

Es ist neu. Es ist ansteckend. Und es schlägt verdammt schnell zu:

Die neue Racketsportart kombiniert Tennis, Squash und Badminton zu einem völlig eigenständigen Spielsystem. Squash-ähnliche Rackets sorgen für eine perfekte Kraftübertragung und bringen die Speeder® auf rasanten Kurs. Die Speeder selbst sind kleiner und schwerer als die ursprünglichen Federbälle und kommen auf Spielgeschwindigkeiten von bis zu 290 km/h!Idealerweise wird Crossminton auf einem Tennisfeld gespielt, wobei das Feld auf das hintere Viertel reduziert wird. Jedoch wird ohne Netz gespielt, was neuartige und abwechslungsreiche Spielzüge ermöglicht. Aber auch ohne Turnierbedingungen kann man fast überall speeden. Entweder einfach und schnell ohne Spielfeldbegrenzungen, oder mit den Easy Courts auf der Wiese, am Strand oder im Schnee!

Kein Court, keine Regeln, keine Grenzen – vom lockeren Spiel am Strand bis zu adrenalinknisternden Ballwechseln in völliger Dunkelheit. Freies Speeden – Fun und Action dort, wo genug Platz ist. Wind? Kein Problem: einfach Windring über die Kappe rollen – so sind die Speeder windstabil bis zu 3-4 Windstärken!

Mit dem Speed Court wird Tennisplatz, Straße, Strand und Park tauglich für ein heißes Match: Für die Wiese und Strand gibt’s den Easy Court – einfach abzusteckende Spielfelder. T-Lines aus Gummi verwandeln einen Tennisplatz im Handumdrehen in zwei Speed Badminton Courts. Und auf der Straße reicht ein Stück Kreide für Wettkampf nach Punkten! (siehe Regeln)

Schlechtes Wetter oder Winter? Macht nichts: Crossminton lässt sich fast in jeder Halle spielen: Tennishallen bieten ideale Voraussetzungen aber auch die normale Mehrzweckhalle wird durch einfache Handgriffe zum Speed Badminton Court: schnell die Easy Courts oder die T-Lines ausgelegt und los geht’s. Ein Netz wird nicht gebraucht.

Speeden, wenn andere schlafen! Der Night Speeder® macht’s möglich: Knicklicht in die fluoreszierende Schlagkappe laden und schon wird eine Wiese im Park zur Location für ein besonderes Erlebnis: Wie Sternschnuppen sausen die magisch leuchtenden Speeder® durch den Himmel – Nervenkitzel und Fun pur!Tipp: Warten, bis es richtig dunkel ist!

Die Crossminton Regeln sind sehr einfach. Um mit dem Spielen nach Punkten zu beginnen, sind folgende Regeln grundlegend:

Ein Spielsatz endet mit 16 Gewinnpunkten. Bei 15:15 geht der Satz in die Verlängerung, wobei zum Sieg zwei Punkte Vorsprung nötig sind. Ein Match geht über drei Gewinnsätze.

Das Recht des ersten Aufschlags und die Wahl der Seite wird durch das Los entschieden. Aufgeschlagen wird im Block mit 3 Aufschlägen pro SpielerIn.

Jeder gespielte Ballwechsel punktet. Beim Gleichstand von 15:15 wechselt das Aufschlagsrecht nach jedem Punkt. Der Aufschlag wird aus der hinteren Spielfeldhälfte ausgeführt. Beim Aufschlag wird der Speeder® vor dem Körper aus Hüfthöhe aus der Hand fallen gelassen und dann geschlagen. Den ersten Aufschlag des nächsten Satzes hat derjenige, der im vorherigen Satz verloren hat.

Infos zum Trainingsbetrieb https://www.tsv-poing.eu/2020/06/11/crossminton-aktueller-trainingsbetrieb/

Infos zum Trainingsbetrieb https://www.tsv-poing.eu/2020/06/11/crossminton-aktueller-trainingsbetrieb/

Gründungsdatum ist der 11.01.20213

Bereits kurz nach unserer Gründung haben wir an den Wettkämpfen der 1. Speed Badminton Bundesliga Süd mit erst einer, dann zwei Mannschaften pro Saison teilgenommen.

Ein langes Wochenende ging zu Ende und mit ihm die Poing Open 2015.

Für die Speedfires war das Turnier überaus erfolgreich, obwohl viele Spieler zum ersten Mal Turnierluft schnupperten. So auch einige unserer Jugendspieler, die gleich mit sehr guten Ergebnissen aufwarten konnten.

Marie gewann Gold in der Kategorie U12, Mona holte sich den 3. Platz. Ebenfalls Bronze ging an Katrin, die aufgrund mangelnder Anmeldungen bei der U14 sich in der U18 gegen lauter Jungs durchschlagen musste.

Auch bei den Erwachsenen ging es mit den Medaillen Schlag auf Schlag. Bei den Senioren Ü40 erkämpfte sich Hugo den zweiten Platz, genauso wie im Herrendoppel mit seinem Spielpartner Sebastian, der sich Bronze in der Einzelkonkurrenz der Herren holen konnte. Dort sicherte sich Paul Silber, der sich in einem sehr spannenden Finale nur knapp seinem Gegner aus Bautzen geschlagen geben musste. In der Damenkategorie gewann Anna Gold, Sandra erreichte den dritten Platz.

Die Treppchenplätze in jeder Kategorie komplettierten Anna mit Paul und Vivien mit Roy schließlich am Sonntag noch im Mixed Doppel mit Silber und Bronze.

Riesen Dank an alle Teilnehmer, dass ihr euch auf den Weg zu uns gemacht habt! Wir haben uns über jeden einzelnen von euch gefreut! Besonders natürlich über die mit weiter Anreise vom KSBV – Kölner Speed Badminton Verein 2010 e.V., den Füchsen und Gekkos aus Berlin, den Red Devils Bautzen und den ERZGEBIRGS-SPEEDYS! Auch nicht zu vergessen die Knightspeeder Nürnberg, SpeedLights München und Fürsty Speeders.

Wir hoffen, es hat euch gefallen und fänden es toll, euch mal wieder hier im Süden begrüßen zu dürfen!

Alle Ergebnisse findet ihr hier: https://goo.gl/2Ljh4S

Wegen einer seitens des Badmintonverbands herbeigeführten Namensdiskussion, hat sich die Crossminton-Community mehrstimmig für einen neuen Namen für diese rasante, coole, querfeldein zuspielende Sportart ausgesprochen:

Am 01.01.2016 wir aus Speed Badminton das heute bekannte Crossminton.

Zum zweiten Mal fand in dieser Wintersaison der Munich Cup statt, ein Turnier, das der Fürstenfeldbrucker Charly Knobling unter den drei Vereinen in und um München organisiert, den FürstySpeeders, Speedlights München und Poing Speedfires. Pro gewonnenen Satz gibt es einen Punkt in insgesamt 10 Spielen, die auf drei Gewinnsätze gespielt werden. Am Ende gewinnt, wer die meisten Punkte gesammelt hat.

Paul, Roy, Sebastian und Anna begaben sich auf eine lange Reise, um 700 km nordwestlich von Poing im verregneten Münster auf den Westfalen Open anzutreten. Den Spielern in der Halle konnte das Wetter draußen natürlich egal sein und so wurde voller Motivation mit der Sonne im Herzen aufgespielt.

Der Vormittag begann mit Doppelspielen. Roy und Sebastian holten sich in der ersten Runde in einem spannenden Duell gegen zwei holländische Spieler einen verdienten Sieg. Im Viertelfinale trafen sie auf das starke Doppel Soos/Stemme vom KSBV – Kölner Speed Badminton Verein 2010 e.V. und mussten sich leider geschlagen geben. Paul und Anna gewannen nach einem Freilos ebenfalls ihr erstes Spiel gegen zwei Wolfsburger. Das Halbfinale war anschließend äußerst umkämpft, im dritten Satz fehlten letztendlich die entscheidenden Punkte und somit blieb es bei einem guten dritten Platz.

In einem hochkarätig besetzten Herrenfeld hatten es unsere Speedfires nicht leicht. Für Sebastian reichte es mit einem Sieg und zwei Niederlagen leider nicht zum Weiterkommen, genauso wenig für Roy, der sich aber sehr stark einen Satzgewinn gegen Daniel Zabel, den Gruppenkopf aus Münster, erkämpfte. Paul hingegen erreichte als Gruppenzweiter das Achtelfinale, das er gegen den Holländer Marcel Van Der Laan sehr konzentriert und sicher gewann. Im Viertelfinale traf er -wie so oft- auf Sönke Kaatz von den Elbspeeders eV aus Hamburg. Trotz vollen Körpereinsatzes und starker Ballwechsel war der spätere Turniersieger nicht zu bezwingen und für unseren Paul Endstation.

Bei den Damen war das Feld relativ klein, jedoch nicht zu unterschätzen. Anna, an eins gesetzt, ging als Gruppenerste aus der Gruppenphase hervor und traf im Halbfinale auf Nina Korte vom KCV Köln. Dieses Spiel entschied sie in zwei Sätzen für sich und fand sich nun im Finale Patricia Arendarski aus Hamburg gegenüber, gegen die sie in der Gruppe bereits ein sehr umkämpftes Dreisatzspiel bewältigt hatte. Das Finale sollte nicht anders werden. Den ersten Satz holte sich Anna, im zweiten dominierte hingegen Patricia. Der dritte Satz stellte sich wieder als äußerst eng und ausgeglichen dar, die beiden schenkten sich in vielen temporeichen Ballwechseln nichts. Zum Schluss lag jedoch das Quäntchen Glück auf Annas Seite und sie gewann den Entscheidungssatz mit 16:14.

Ein tolles Ergebnis, das am Abend nach 12 Stunden in der Halle gebührend gefeiert wurde.

Nach dem Ausschlafen am Sonntag meinte es Petrus dann doch noch gut mit unseren Speedfires und bescherte ihnen auf der Sightseeing Tour durch Münster strahlenden Sonnenschein und eine gute Heimreise.

Ein riesiger Dank geht an dieser Stelle an den Crossminton SV Blau-Weiß Aasee Münster! Großartige Organisation, reibungsloser Ablauf und das beste: die Verpflegung! Wir kommen gerne wieder

#crossartig #crossminton #crossmünston #beachenrockt

Da haben sich die 1222km gelohnt: Anna nimmt den Deutschen Meistertitel von Hameln mit nach Hause (das ist sooooooo #crossartig !!!), Paul verliert erst aber wie immer im Viertelfinale gegen Sönke Kaatz, Sandra hatte auf ihre Chance in der Ü35-Gruppe gehofft die kam aber nicht zustande (die Gruppe) und Sebastian schrammt nach toller Leistung ganz knapp am Achtelfinale vorbei.

Nach dem Sieg ist vor dem Sieg dachte sich unsere Anna. Nachdem sie letztes Wochenende die ICO 2nd Westfalen Open 250 gewann fuhr sie einerseits entspannt aber andererseits auch mit etwas Erfolgsdruck zu dem Treffen der besten deutschen Spieler zu den Deutschen Meisterschaften 2016 im weit entfernten aber schönen Hameln. Mit im Gepäck waren die Speedfires Sandra, Sebastian und Paul.

Sandra hatte doppelt Pech da erst einmal ihre erste Teilnahme in der Ü35 Gruppe nach ein paar kurzfristigen Absagen nicht zustande kam und sie dann auch noch in Annas sehr starke 5er Gruppe gelost wurde. Obwohl sie ihre Gegnerinnen gut in der Gegend herum scheuchte, konnte sie sich am Ende nicht durchsetzen. Anna dagegen gewann drei ihrer vier Gruppenspiele souverän und musste dann nach einem heftig umkämpften Dreisatz-Stundenkrimi (na ok, offiziell 55 Minuten) gegen die aktuelle Ranglistenerste Andrea Horn bereits im Halbfinale gegen die Titelverteidigerin und Favoritin Franziska Ottrembka ran. In einem allgemein bewunderten und extrem druckvollen Spiel ging es hin und her. Nach einigen einfachen Fehlern im ersten Satz und äußerst platzierten Smashes der Gegnerin kam Anna im zweiten immer besser rein und konnte immer mehr ihr eigenes Spiel durchsetzen. Trotzdem mussten 2 Matchbälle abgewehrt werden und der dritte Satz musste entscheiden. Anna parierte die starken Smashes weiterhin fantastisch, machte selber Druck und konnte schnell ein paar Punkte Vorsprung herausspielen. Auch als Franziska ihr Spiel umstellte, blieb Anna konzentriert und flink auf den Beinen. Nach sehr kraftraubenden und langen Ballwechseln gab es die ersten Matchbälle bis es tatsächlich hieß: FINALE Anna!

Dort wartete Verena Horn, die im anderen Halbfinale ihre Schwester Andrea ausgeschaltet hatte. In dem würdigen Finalspiel gab es von beiden Seiten kaum Schwächen und viele tolle Bälle zu bewundern. Nach dem ersten umkämpften Satzgewinn behielt Anna die Nerven, Kondition und Präzision und erkämpfte sich sogar in zwei Sätzen verdient den deutschen Meistertitel 2016!!!

Neben dieser fantastischen Leistung darf man aber auch die männlichen Speedfires in ihrem hochkarätigen Feld (u.a. 9 der Top 12 Spieler waren da) nicht ganz vergessen. Sebastian und Paul hatten leider ebenfalls das Pech in dieselbe Gruppe gelost worden zu sein, zusammen mit Christian Matthes aus Bautzen und Niklas Feierabend von den Elbspeeders Hamburg. Die vier spielten allesamt auf sehr hohem Niveau und schenkten sich in anstrengenden Battles keinen Meter. Sebastian zeigte seine beste Turnierleistung, spielte sehr konzentriert und mutig auf und triumphierte mit diesem Rezept über den Favoriten der Gruppe, Christian Matthes. Im vereinsinternen Duell ging es erneut hoch her, erst im dritten Satz konnte sich Paul knapp durchsetzen, verlor jedoch wiederum gegen Niklas. Somit stand es nach vier von sechs Spielen Unentschieden unter allen vier Konkurrenten, die letzten beiden Matches mussten über das Weiterrücken entscheiden. Hier traf Sebastian auf den jungen Hamburger. Sie begegneten sich auf Augenhöhe und wieder gab erst der dritte Satz den Ausschlag zu Ungunsten Sebastians, der sich damit leider nicht für die Finales qualifizieren konnte aber dennoch ein großartiges Turnier gespielt hat!

Nun musste Paul noch gegen Christian ran, keinen unbekannten Gegner. Zwar zog sich das Spiel einmal mehr über drei Sätze, doch Paul blieb hoch konzentriert, entschärfte viele der Mattheschen Killer-Angaben und erkämpfte sich den Sieg und damit den Einzug ins Achtelfinale gegen Sebastian Kloss von den Füchsen Berlin. Ein weiteres Dreisatzspiel, ein weiterer Sieg und ein weiteres Mal Sönke Kaatz aus Buxtehude als Viertelfinalgegner. „Alles gegeben, richtig hammermäßiges Spiel, trotzdem hats leider wie immer nicht gereicht“, so Pauls Resümee unter Wadenkrämpfen, aber glücklich über ein tolles Turnier.

#crossartig #crossminton #deutschminton #crossmeisterin

Mit dem letzten Punktspiel am 08.10.2016 stand die Tabelle in der 1. Bundesliga Süd fest. Die 1. Mannschaft von Poing setzt sich denkbar knapp gegen die Münchner Speedlights durch, mit einem guten Vorsprung auf die drittplatzierte Spielgemeinschaft Bonlanden/Heidelberg.

Bis zum letzten Spieltag hing der Ausgang der Liga für die ersten beiden Platzierungen in der Luft. Mit einer souveränen Leistung konnten die Poinger die Nürnberger Knightspeeders mit einem umkämpften aber am Ende glatten 6:0 besiegen. Damit zog Poing I an den punktgleichen Münchnern wegen einem besseren Spielgewinnverhältnis vorbei.

Das Mega-Crossminton-Wochenende bei uns in Poing ist aus und vorbei und es war ein voller Erfolg! 6 Podestplätze, vier mal so viele Stunden in der Halle und noch viel mehr glückliche (wenn auch leicht geschaffte) Gesichter, so das Fazit der Deutschen Doppelmeisterschaften und der Poing Open 2016.

Los ging es am Samstagmorgen schon um 8 Uhr früh mit der Deutschen Doppelmeisterschaft, denn es galt einen strengen Zeitplan einzuhalten. Sehr starke Konkurrenz aus allen Ecken Deutschlands machten es den 15 teilnehmenden Speedfires nicht leicht. So war für Dennis und Tobias, die ihr erstes Turnier bestritten, Katrin und Alex, Michael und Caro, sowie für Sebastian, Roy, Michael und Christian mit ihren auswärtigen Doppelpartnern leider nach der Gruppenphase Schluss.

Besser lief es im Open Doppel für Paul und seinen Spielpartner Christian Matthes aus Bautzen. Auf eine starke Gruppenphase folgte ein ebenso starkes Viertelfinale. Im Halbfinale gegen den amtierenden Europameister David Zimmermanns und seinen Partner Michael Von Lennep aus Düsseldorf konnten sie zwar gut mithalten, mussten sich aber am Ende geschlagen geben und wurden mit einem tollen dritten Rang belohnt.

Ebenfalls auf dem Bronzerang landete Anna mit ihrem Spielpartner Sönke Kaatz (Buxtehude). Die beiden wollten ihren Mixed-Titel aus dem Vorjahr verteidigen und marschierten ohne Probleme durch die Gruppenphase und das Viertelfinale. Doch im Halbfinale warteten mit den späteren Gewinnern und Nationalspielern Franziska Ottrembka (Berlin) und Robin Joop (Wolfsburg) ein extrem anspruchsvolles Doppel. Entsprechend umkämpft gestaltete sich die Partie. Erst im dritten Satz fiel die Entscheidung und mit 14:16 leider negativ für Anna und Sönke aus. Umso mehr begeisterte Paul, der sich mit Patrizia Arendarski eine starke Hamburgerin ins Boot geholt hatte. Auch sie erreichten das Halbfinale und damit einen tollen dritten Platz.

Relativ unerwarteter kam die Silbermedaille für Sandra und Anna im Damendoppel. Sie zitterten sich durch die Gruppenspiele, nach denen erst der Vergleich der gewonnenen und verlorenen Sätze zwischen drei Teams über ein Weiterkommen entschied. Umso mehr überzeugten sie danach im spannenden Halbfinale gegen das Doppel Nina Korte / Anna Borek. Im Finale hielten sie im ersten Satz sehr gut den Powerschwestern Andrea und Verena Horn aus Dresden entgegen, die jedoch im zweiten Satz deutlich besser ins Spiel kamen und sich schließlich durchsetzten. Sandra und Anna dürfen sich dafür deutsche Vizemeisterinnen nennen.

Die Konkurrenz bei den Poing Open war dieselbe, dementsprechend zeigten sich einige Parallelen. Alle Speedfires kämpften unermüdlich und spielten in Hochform. Trotz eines Aus in der Gruppenphase konnten Katrin, Sandra, Roy und Alex stolz auf sich sein. Ebenso Vivien, die 4 Sätze in 4 Spielen holte, Sebastian, dem zweimal nur ein paar Punkte im dritten Satz gefehlt hatten, Dennis, der bei seinem ersten Turnierauftritt als Nachwuchstalent sehr positiv aufgefallen ist und Lea, die auch ihren ersten Auftritt wunderbar gemeistert hat.

Hugo erreichte nach langer Trainingspause überraschend das Viertelfinale in der Kategorie O40. Leider unterlag er dort gegen Thomas Groß aus München in drei spannenden Sätzen.

Als Zweiter beendete Paul die Gruppenphase. Nach einer gewonnenen Zwischenrunde stand ihm wie immer wenig überraschend im Viertelfinale Sönke Kaatz gegenüber. Paul, trotz allem sehr motiviert, spielte ein überragendes Match und konnte nach einem verlorenen ersten Satz den zweiten für sich entscheiden. Am Ende fehlten leider ein wenig die Kräfte, dennoch lieferte er eine tolle Leistung ab.

Anna gewann erwartungsgemäß ihre Gruppenspiele, genauso das Viertelfinale gegen Verena Horn und das Halbfinale gegen Nina Korte. Das Finale versprach äußerst spannend zu werden, denn als Gegnerin wartete keine geringere als Franziska Ottrembka. Nach einem engen ersten Satz, den Anna für sich entscheiden konnte, erhöhte Franzi den Druck und ließ Anna nur noch wenig Platz zum Reagieren. So holte sich letztenendes die Berlinerin den Poing Open Titel und Anna sicherte sich die Silbermedaille.

Ein tolles Turnier spielte Marie in der Kategorie U14. Sie gewann alle ihre Spiele, verteidigte somit ihren Titel von letztem Jahr und komplettierte den Medaillensatz für die Poing Speedfires!

Herzlichen Glückwunsch an alle Gewinner und Teilnehmer!!

Am 26./27. November trafen sich die jeweils zwei besten Teams der jeweiligen regionalen Bundesligen zum Finalkampf. Aus der Liga Süd reisten die erste Mannschaft der Poing Speedfires und die Münchner Speedlights an. Nach dem 6. Platz letztes Jahr konnten sich die Speedfires diesmal den hervorragenden 5. Platz im landesweiten Vergleich sichern!

Das Team der Poing I – Roy, Hugo, Anna, Paul, Sebastian – reiste am Wochenende bis nach Hamburg um sich dort mit den besten Ligamannschaften Deutschlands zu messen.

Es waren zwei Gruppen ausgelost worden und die Poinger mussten sich zuerst mit den Kölner Speedkrebsen, den Red Devils Bautzen und den Hamburger Elbspeeders messen. Damit hatten wir nicht nur die Gewinner der letzten vier Jahre aus Hamburg, sondern auch noch die späteren Gewinner aus Köln mit in der Gruppe. Somit war klar, dass ein Sieg gegen die Bautzener her musste. Dies gelang auch fulminant und, nach mehreren (aber leider nicht genügenden) gewonnen Spielen gegen die Favoriten, hieß es am Sonntag zum Spiel um Platz 5 gegen die Dresdner Speedbats anzutreten. Wieder wurden ganz starke Leistungen gezeigt und am Schluss stand mit einem 5:1 Sieg der 5. Platz fest womit die Poinger ganz und gar zufrieden sein konnten!

Poinger Crossminton-Spieler stark bei Turnier in Bautzen

Feiner Artikel: http://www.wochenanzeiger.de/article/187587.html

Crossartige Einzel- und Mannschaftsleistung der Poing Speed Fires 2016

So wie in den vergangen zwei Jahren wurden auch dieses Jahr so einige Spieler der Crossminton-Abteilung des TSV Poing e.V. für ihre fantastischen, sportlichen Leistungen bei der Sportlerehrung Ebersberg und der Sportlerehrung in Poing ausgezeichnet.

Allen voran Anna Hubert. Amtierende Deutsche Meisterin im Damen-Einzel und Deutsche Vizemeisterin im Damen-Doppel. Siegerin der German Open, Westfahlen-Open, Munich Beach-Open und jede Menge weitere Medaillenplätze um nur ein paar zu nennen. Als zweiten Paul Holleis. Neben seinem Trainerdasein auch ein guter Einzelspieler und hat seine Ehrung für zahlreiche Medaillen und super Platzierung zurecht verdient. Der Dritte im Bunde ist Sebastian Bruszies. Welcher genauso stolz auf seine Leistungen im Medaillenranking sein darf. Nummer vier und fünf sind Roy Gralke und Hugo Escudero.

Alle fünf zusammen erkämpften sich zum wiederholten den Liga-Süd-Meistertitel und seit dem Bundesliga-Finalturnier sind sie deutschlandweit die fünftbeste Mannschaft (Poing Speed Fires I).

In diesem Jahr zum ersten Mal für seine erfolgreichen Turnierteilnahmen dabei, und auch völlig zurecht, Christian Enzinger.

Auch die Jugendabteilung der Crossminton-Abteilung, des TSV Poing e.V., kann sich sehen lassen und kann mega stolz auf ihre erbrachten Leistungen sein. Hier besonders hervorzuheben ist unsere „Gold“-Marie Schubert, die ihren Titel, vom vorletzten Jahr, in der Altersklasse U14, bei der Poing Open verteigen konnte.

Ebenso stark zu bewerten sind die Erfolge (3. Platz German Open AK U18, 7. Platz bei den Deutschen Doppelmeisterschaften und und und) von Katrin Huber.

Last but not least, Sandra Hesse die zu Recht stolz auf ihren Vizemeistertitel im Damen-Doppel mit Anna Hubert ist. Ebenso auf den 9. Platz im Mixed-Doppel (Partner Sebastian Christoph/ Nürnberger KnightSpeeder) und der 10. Platz im Damen-Einzel AK

Ü35 bei den European Championships in Frankreich.

Glückwunsch an alle Geehrten und ein dickes Dankeschön an alle Poing Speed Fires die im Hintergrund Daumendrücken und immer helfen, wo es nur geht.

Insgesamt betrachtet, war das Jahr 2016 – in dieser kurzen Zeit, seit es diese Abteilung

gibt – eines der erfolgreichsten und wir hoffen, dass es auch weiterhin den einen oder

anderen Titel/ Medaillenplatz für uns geben wird.

Zwei Poing Speedfires erreichen bei den ICO Crossminton Weserbergland Open 2017 den 3. bzw. 9. Platz. Damit schieben sie sich auf Platz 3 und 12 der Deutschen Rangliste hinauf!

Ausnahmsweise mal ganz gemütlich machen sich die beiden Speedfires Sebastian Bruszies und Paul Holleis auf den Weg nach Hessisch Oldendorf zu den Weserbergland Open 2017. Auf dem Weg dorthin nehmen sie noch den Münchner Alexander (Sascha) Naumann und den Nürnberger Sebastian Christoph mit. Das heißt, eigentlich nimmt dann Sebastian C. spontan alle anderen mit, da das Poinger Gefährt den Geist aufzugeben droht …

Samstag Abend werden von der kleinen Gruppe der „Knightspeedfirelights“ noch die letzten Taktiken durchgesprochen bevor es dann am Sonntag um 8 Uhr in die Halle geht. Alles wie gewohnt hervorragend organisiert von den Crossminton-Leuten des Time Sports e.V. inklusive Handy-App zum Punktezählen!

In der Herren (bzw. Open) Kategorie hatten sich 10 der Top-15 Spieler in Deutschland angemeldet. Dementsprechend kompetitiv gestalten sich die Gruppen. Sascha erwischt einen unglücklichen Start und scheitert in der Gruppenphase. Unser Nürnberger Freund Sebastian C. kann sich als Gruppenzweiter fürs Achtelfinale qualifizieren, verliert da aber (zu) deutlich gegen Niklas Feierabend aus Buxtehude.

Unser Sebastian dagegen spielt von Anfang an hervorragend und konzentriert auf und gewinnt das wichtige Spiel gegen ‚Gastgeber‘ Maximilian Franke stark mit 17:15, 14:16, 14:16. Als er dann noch Michael Neutzsch aus Berlin in drei und den Münsteraner Max Schubert in zwei Sätzen besiegt, ist der Gruppensieg klar und damit der Einzug ins Achtelfinale gesichert. Dort ist allerdings Schluss gegen Daniel Zabel aus Münster, da er sich erst zu spät an dessen sehr starken und platzierten Smashes aus jeder Lebenslage gewöhnen kann. Aber eine starke Leistung und eine erfolgreiche Rückmeldung in die Turnierszene!

Paul kann sich in der Gruppe relativ ungefährdet gegen den eigentlich Ü40-Spieler Andre Noll durchsetzen und schnell einen zweiten Sieg gegen den Niederlaender Geuverink einfahren. Einzig der Münsteraner Joschka Wunderlich kann ihm noch den Gruppensieg nehmen, was ihm auch in zwei knappen Sätzen gelingt. Als Gruppenzweiter wartet dann der Berliner Sebastian Kloss im Achtelfinale, was, wie in der Vergangenheit auch, ein sehr enges Spiel wird.

Der erste Satz geht noch relativ klar an Paul, der zweite dafür noch klarer an Sebastian K. Im dritten Satz kann sich Paul nach einem anfänglichen Rückstand wieder herankämpfen. Die entscheidende Szene dann bei 11:11: Paul erspringt sich noch einen schön platzierten Ball, kann dann den nächsten noch halb liegend retournieren und kommt wieder ins Spiel. Als Sebastian dann versucht die Gelegenheit zu nutzen aber dabei knapp ins Aus spielt, ist natürlich das Selbstvertrauen auf der einen Seite groß und auf der anderen Seite erschüttert und der entscheidende Satz geht an Paul.

Im Viertelfinale trifft er dann auf Daniel Zabel (siehe oben). Glücklicherweise kommt dieser nicht so recht ins Spiel und Paul kann den ersten Satz gewinnen. Im zweiten wird er aber regelrecht abgeschossen und aus einem 2:7 Rückstand wird schnell ein 6:15. Siegessicher versucht Daniel einen der Satzbälle zu verwandeln, macht aber dabei einen Fehler nach dem anderen. Paul bleibt konzentriert und plötzlich steht es schon nur noch 11:15. Daniel wird sichtlich nervöser und als dann noch bei 14:15 ein Smash nur hauchdünn vor der Linie landet ist plötzlich wirklich wieder alles offen. Und tatsächlich gewinnt Paul den zweiten Satz und steht im Halbfinale!

Nach diesen beiden kuriosen Spielen steht, wie eigentlich auf jedem Turnier, die deutsche und internationale Nummer 1, Sönke Kaatz auf der anderen Seite. Und wie jedes Mal wird es ein schön anzusehendes Spiel: Sönke mit offensivem Spiel von überall, Paul mit viel Einsatz und Reaktion auf eine Konterchance wartend. Ebenso wie immer kann sich Paul aber nur kurz eine Führung herausspielen und am Ende ist Sönke einfach viel zu konstant und stark. Trotzdem mit 13:16, 10:16 ein Ergebnis das sich sehen lassen kann und damit ein nicht unverdienter 3. Platz und 100 Punkte für die Rangliste – damit steht endlich mal ein Poinger unter den Top 3 Spielern auf der deutschen Rangliste der Open Division!

Vielen Dank an Sebastian, Sebastian und Sascha, die mit der Rückfahrt noch gewartet haben dass Paul noch das Treppchenplatz-Foto von sich bekommen konnte. Nachdem alle gegen 4 Uhr früh zu Hause waren, geht es kommende Woche schon wieder in den Norden zu der ersten Runde des DCV Mannschaftspokals nach Bautzen.

In der Vorrunde vom ersten DCV Mannschaftspokal-Wettbewerb sichern sich die Poing Speedfires den 2. Platz.

Dieses jahr gestaltet der DCV (Deutscher Crossminton Verband) erstmals den DCV Mannschaftspokal. Alle Liga-Mannschaften Deutschlands konnten sich dafür anmelden. Natürlich sind die Poing Speedfires mit am Start!

Die durch die Platzierung in den letzten beiden Jahren der Bundesliga mitbestimmten Auslosung bringt uns zusammen mit den Red Devils Bautzen und der zweiten Mannschaft der Füchse Berlin. Austragungsort: Bautzen. Das heißt mal wieder gut 10 Stunden Fahrt, in dem Fall sogar an einem Tag. Also früh aus dem Bett um uns dankenswerterweise von Alex abholen zu lassen.

Um 13 Uhr geht’s los mit der Partie Poing-Berlin. Nachdem Anna einen klaren und Paul einen sehr knappen Sieg im Einzel einfahren können gehen Roy und Alex schon mal mit einem kleinen Vorsprung in Ihre Einzelpartien. Roy hält sich stark gegen den Berlin-Österreichischen Veteranen Markus Hellauer und verliert den ersten Satz nur knapp mit 15:17. Weiter stark spielend holt er sich den zweiten Satz und muss sich wieder nur eng im dritten Satz geschlagen geben. Starke Leistung! Im vierten Einzel zeigt Alex bei seinem ersten offiziellen Auftritt für die Poinger gleich was er kann und bringt den Berliner Jones Spaeth arg in Bedrängnis. Der versucht es dann noch mit Hinhaltetaktik, aber mit viel Konstanz und Laufleistung bringt uns Alex mit 3:1 in Führung!

Da das Berliner Herrendoppel sehr stark zu sein droht, beschließt Sandra auf Nummer sicher zu gehen und gibt Ihren Platz im Mixed an Anna ab. Sehr starke Aktion! Ob das Mixed nicht auch anders gewonnen worden wäre bleibt leider offen, so aber steht am Ende ein relativ sicheres 4:2 für Poing im Buch!

Das zweite Spiel des Tages: Poing gegen Bautzen. Da unser Sebastian leider nicht mitkommen konnte, steht die etwas geschwächte Poinger Mannschaft diesmal der vollen Stärke der Bautzener gegenüber. Das Dameneinzel gewinnt Anna souverän, im ersten Herreneinzel steht Paul sein beliebter Doppelpartner aber ansonsten Erzrivale Christian Matthes gegenüber. Natürlich muss der dritte Satz die Entscheidung bringen. Und leider, nach Brillen- und Schulterproblemen, einer gerissenen Saite, einer unglücklichen Entscheidung und anderen Ausreden geht das Spiel an den unerschütterlich spielenden Bautzener.

In dem nächsten Einzel schlägt sich Roy fantastisch und kann dem stark aufspielenden Stephan Weise („Hu!“) gut Paroli bieten und ihn immer wieder überraschen; trotzdem gehen die Bautzener mit 1:2 in Führung. Alex in seinem zweiten Einzel an dem Tag kann sich mit einer super Leistung den ersten Satz gegen Michael August erkämpfen, verliert dann aber den zweiten. Im Dritten Satz hatte sich der Bautzener dann stark gespielt und trotz wunderbarer Gegenwehr steht es nun 1:3.

Das Doppel Roy-Alex und das Mixed Sandra-Paul versuchen alles um noch ein Unentschieden zu erreichen. Im Mixed gegen Matthes/Selge klappt es auch tatsächlich in einem spannenden Dreisatzmatch, da die Bautzener vermutlich nicht ausreichend mit Sandras Schnelligkeit und Sicherheit gerechnet hatten! Leider müssen sich Roy und Alex in einem crossartigen Herrendoppel in drei Sätzen geschlagen geben, der Endstand also 2:4 gegen Bautzen.

Da Bautzen auch noch 4:2 gegen Berlin gewinnt, bedeutet das den 2. Platz für uns und damit banges warten auf die anderen Gruppenspiele in den nächsten Wochen, denn nur einer von drei zweiten Plätzen kommt weiter.

Insgesamt aber ein wunderbarer Spieltag, eine schöne Atmosphäre und sehr sympatische Spiele. Hervorragend organisiert von den Red Devils Bautzen, vielen Dank!

Anna marschiert durch zum Turniergewinn und sichert sich auch noch den zweiten Platz im Mixed. Sebastian schafft nach einigen Kraftakten den Gruppensieg und muss sich wie Paul erst im Achtelfinale gegen 22:30 Uhr geschlagen geben. Im gemeinsamen Doppel werden sie 9. nach einem frühen und knappen 13:16, 14:16 Aufeinandertreffen gegen die späteren Turniersieger.

Slowenien ist gar nicht so weit weg dachten sich ein paar Poing Speedfires und fuhren deshalb auf die Slovenian Open 2017 nach Lasko.

Während Anna schon in der Früh unterwegs war und sich schon mal einen sonnigen Eindruck von der Gegend machte, konnte sich Sebastian erst nachmittags loseisen und so kamen er und Paul pünktlich 3 Minuten vor Hotel- und Gaststättenschließzeit an. Die dortige Gastfreundschaft verschaffte ihnen aber doch noch die erste Pizza des Wochenendes und einige Stunden Schlaf als Vorbereitung.

Gleich um 9:00 Uhr früh beginnen die Doppel. Sebastian und Paul kommen sofort gut ins Spiel, haben mit ihren tschechischen Kontrahenten relativ leichtes Spiel und ziehen damit nach einem 2:0 Sieg bereits ins Achtelfinale ein. Dort warten leider schon die Topfavoriten S. Kaatz und R. Joop. In einem starken und erstaunlich umkämpften Spiel geben die Speedfires einiges an Gegenwehr und verlieren den ersten Satz nur knapp mit 13:16. Der zweite Satz ist sogar noch umkämpfter; allerdings verhelfen zwei unnötige Fehler nach einem 14:14 den späteren Turniersiegern dann doch zu einem verdienten Sieg.

Besser läuft es bei Anna in ihrem Mixed mit dem schwedischen Topspieler M. Ekberg der später bei den Herren dominieren sollte. Ohne Satzverlust schaffen Sie den Weg ins Finale. Dort unterliegen sie nur ganz knapp in drei Sätzen nach einem hochkarätigen Spiel dem aktuellen Europameister D. Zimmermanns mit Partnerin.

Die Sporthalle mit elf Plätzen ist schön groß und gut spielbar. Allein die roten (statt gewöhnlich gelben) Markierungen und der Bodenbelag mit einigen Farbwechseln sind gewöhnungsbedürftig. Die allgemeine Organisation, Spieleinteilung, Ansagen und Livescoring sind top wie gewohnt von den sympathischen Ausrichtern von Krosmintonska zveza Slovenije. Allerdings ist die einzige wirkliche Möglichkeit etwas zu essen zu bekommen der lokale Pizzadienst. Gut und schnell aber es bedeutet für die Poinger Spieler um 14 Uhr die zweite, um 18 Uhr die dritte und um 23 Uhr die vierte Pizzamahlzeit innerhalb von 24 Stunden. Sicherlich wurden nach gemeinschaftlichen 20 Spielen die meisten ungesunden Stoffe wieder abtrainiert, trotzdem wird Pizza erstmal nicht auf dem Speiseplan stehen…

Zwischendurch laufen die Einzelspieler in Gruppenphasen an. Da die Weltranglistenerste J. Keber leider kurzfristig absagen musste, hat Anna wenig Probleme sich in ihrer Gruppe an die Spitze zu spielen. Weiter geht es damit direkt ins Halbfinale gegen die Weltranglistenfünfte D. Knez. Anna lässt sich hier gar nicht auf ein langes Spiel ein und macht von Anfang an Druck. Die Gegnerin ist überrascht und findet nicht so recht in ihr Spiel. Nach einem erstaunlich schnellen Satzgewinn geht es in den zweiten. Anna spielt weiter fantastisch und platziert auf und schon bald steht die Finalteilnahme nach einem wunderbaren 16:9, 16:9 fest!

Dort trifft sie auf die weltweit auf Platz 9 gesetzte und heute durchgängig besonders stark auftretende Lettin S. Paegle. Ein sehr strategisches Spiel entwickelt sich mit vielen gegenseitigen Chancen und Rettungsaktionen. Beide spielen sehr stark und druckvoll aber Anna kann von Anfang an besser punkten und hält die Führung bis zum 16:9 durch. Im zweiten Satz steigert sich Paegle weiter und weiter und holt Annas anfängliche Führung langsam aber sicher auf. Am Ende aber führt kein Weg daran vorbei dass Anna die bessere Leistung auf den Platz bringen kann und damit absolut verdient die 1000 Punkte nach Hause bringt! Genial!

Paul startet in das Turnier gleich mit dem wichtigsten der drei Gruppenspiele gegen einen jungen Slovenen. Wie eigentlich immer kommt er schwer ins Spiel und verliert den ersten Satz 11:16. Er kann sich aber steigern und kann sich deutlich mit 16:5 in den dritten Satz spielen. Dort behält er konstant die Oberhand und gewinnt das schön anzusehende und sehr abwechslungsreiche Spiel.

Die anderen beiden Spiele laufen nahezu wie vorher erwartet. Das eine ein deutlicher Sieg, das andere gegen den weltranglistendritten Schüsseler wunderbar umkämpft. Unerwarteterweise gewinnt Paul den ersten Satz und hat sogar einen Matchball als aber dann doch die Erfahrung des Ex-Weltmeisters zuschlägt und Paul doch noch im dritten Satz verliert. Als Gruppenzweiter geht es aber weiter. Kurz vor der dritten Pizza heißt es dann Achtelfinale gegen den slowenischen Nationalspieler S. Lipuscek. Der ist allerdings eine Klasse besser und Paul nach 23 Stunden in der Halle nicht mehr wirklich fit. Eine klare 0:2 Angelegenheit aber mit 340 Punkten für die Rangliste ein absolut zufriedenstellendes Ergebnis!

Sebastian’s Fünfergruppe besteht nach der kurzfristigen Absage des Wolfsburgers J. Jöhnk nur noch aus vier Spielern. Der erste Gegner kann ihm nicht viel entgegensetzen, ein klares 2:0. Danach allerdings ein evtl entscheidendes Spiel gegen den starken und erfahrenen Turnierspieler O. Vincze aus Ungarn. Sebastian packt gleich sein konzentriertes Präzisionsspiel aus und überrascht den Ungarn in dem er einfach alle Schmetterbälle erwischt oder ins Aus segeln lässt.

Der erste Satz geht etwas daher vielleicht etwas überraschend klar aber absolut verdient an Sebastian. Sein Gegner hadert immer mehr mit sich selber und versucht sein Spiel mehrfach umzustellen. Sebastian zeigt sich unbeeindruckt und gewinnt auch noch den zweiten Satz nach einer kurzen Aufholjagd mit 17:15. Fantastische Leistung!

Weiter geht’s mit dem letzten Gruppenspiel gegen den Routinier T. Dozsa um den Gruppensieg. Es entwickelt sich zu einem unheimlich laufintensiven und anstrengenden Spiel. Beide sind sehr konzentriert, stehen gut und versuchen mit variantenreichem Spiel eine Lücke zu finden. Im ersten Satz gelingt das Sebastian besser und erspielt sich die 1:0 Führung. Im zweiten packt Dozsa seine lange Erfahrung aus, spielt mehr auf Sicherheit und erringt sich ein enges 16:13. Der dritte Satz muss entscheiden. Lange Zeit sieht es so aus als wolle sich der Satz dem allerdings verweigern. Immer wieder ein Punkt hier, einer da. Schließlich aber doch eine wichtige 14:10 Führung von Sebastian herausgespielt. Immer weiter auf Konter bedacht, spielt sich Dozsa wieder heran; aber stark und fokussiert behält Sebastian die Nerven und schafft das 16:13!

Damit zieht Sebastian in das Achtelfinale ein, das auch tatsächlich noch am gleichen Tag um kurz nach 22 Uhr angefangen werden muss. Etwas mitgenommen von den anstrengenden Spielen kann er hier dem deutschen Vizemeister A. Lutz nicht genug entgegensetzen. Aber ein hervorragender und wohlverdienter 9. Platz in diesem so stark besetzten internationalen Turnier!

Insgesamt also ein erster Platz, ein zweiter Platz, und dreimal neunter – für die Speedfires genau wie für die drei Spieler selbst ein crossartiger Erfolg!

Wanderpokal des MunichCup 2017 bleibt in Poinger Hand: Plätze 1-3: Paul, Sebastian, Anna

Wie schon in den vergangen zwei Jahren wurde zur Überbrückung der Ligapause im Winter der MunichCup ausgetragen. Gestartet wurde im November 2016 mit Ende März 2017. In den zehn Spieltagen (1 Spieltag = 2 Wochen ) wurde nach dem Schweizer Spielsystem im Modus „Best of 5“ gespielt, was den einen oder anderen doch ganz schön an seine sportlichen Grenzen brachte. Jeder gewonnene Satz ergab 1 Punkt. Nach jeder Runde wurden die Spieler mit gleicher bzw. ähnlicher Punktzahl für die nächste Begegnung ausgelost.

Die Kampfeslust der Poinger, die Platzierungen vom Vorjahr (Platz 1 Sebastian, Platz 2 Anna, Platz 3 Paul und jede Menge weitere gute Platzierungen) wieder zu erreichen, hatte sich bestätigt, nur in anderer Reihenfolge. Paul gewann insgesamt mit 28 Punkten – nach vielen stundenlangen, spannenden Spielen, welche immer erst im 5. Satz die Entscheidung brachten – dieses Mal den Titel und den Wanderpokal. Sebastian belegte, trotz starker Gegenwehr und 26 Punkten Rang 2. Anna erkämpfte sich, denkbar knapp mit 25 Punkten, Rang 3. Weitere super Platzierungen von Roy Platz 7, Alexander M. und Christian teilen sich Rang 10 und Vivien Platz 15.

Alles in allem ein wunderbares Turnier (Organisator: Charly Knobling von den Fürsty Speeders), welches traditionell im Restaurant „Vierwasser“ (Fürstenfeldbruck) gebührend mit einer gemeinschaftlichen Siegesfeier beendet wurde.

Zum Auftakt der Sommer-Turniersaison letztes Wochenende machten sich die drei Speedfires Anna, Paul und Sebastian im Schneetreiben auf nach Münster zu den 3. Westfalen Open und holten Platz 1 im Dameneinzel und Platz 3 im Herrendoppel!

Begonnen wurde mit den Doppelspielen im KO-Runden-System. Auf Anna und ihren Mixed-Partner Stefan aus Köln warteten in der ersten Runde gleich die späteren Sieger Nina und Jonas (Köln/Wolfsburg). Diese konnten sich das Weiterkommen nach einem spannenden Dreisatzmatch sichern. Für das Speedfires Duo Sebastian und Paul lief es besser. Sie überstanden souverän die erste Runde, nachdem ihre Gegner krankheitsbedingt ausfielen. Im Viertelfinale bewiesen sie dann ihre Stärke und zogen ohne zu wackeln ins Halbfinale ein. Dort zeigten sie sich sehr kämpferisch, mussten sich schließlich doch David und Adrian aus Köln und Münster geschlagen geben. Trotzdem super Leistung und die erste Medaille des Tages für die Speedfires!

In den Einzelkategorien wurde es gleichfalls spannend. Sebastian setzte seine starke Turnierleistung in diesem Jahr fort und sicherte sich in einer nicht zu unterschätzenden Gruppe als Gruppenerster den Einzug ins Achtelfinale. Auch Paul hatte eine starke Konkurrenz in seiner Gruppe und kam als Gruppenzweiter ins Achtelfinale. Dort erwartete ihn Bouba aus Köln. Nachdem Paul den ersten Satz für sich entschied, fand er in Satz 2 und 3 kein Mittel mehr gegen seinen Gegner und musste die Segel streichen. Sebastian stand dann im Viertefinale ebenfalls Bouba gegenüber. Im Gegensatz zu Paul holte er sich nicht den ersten, sondern den zweiten Satz, konnte im dritten aber nicht an seine Leistung anknüpfen und blieb somit auf einem guten 5. Platz.

Das Damenfeld war zwar denkbar klein, nichtsdestotrotz auf hohem Niveau. Annas erstes Gruppenspiel gegen die Münsteraner Lokalmatadorin Jana mutete eher einem Finale an und zog sich äußerst spannend und ausgeglichen über drei Sätze mit dem besseren Ende für die Poingerin, genauso wie die anderen Gruppenspiele und das Halbfinale. Im Finale wartete dann tatsächlich wieder Jana. Nach einem knappen ersten Satz machte Anna diesmal im zweiten den Sack zu, holte sich den Sieg und verteidigte somit ihren Titel aus dem letzten Jahr.

Herzlichen Glückwunsch an alle Gewinner und riesen Dank an den Crossminton SV Blau-Weiß Aasee Münster für die tolle Organisation dieses fast schon Traditionsturniers mit sensationeller Verpflegung und einer Playersparty, an der es nichts auszusetzen gab.

Als bester Gruppenzweiter der drei Vorrunden des DCV Mannschaftspokals 2017 qualifizierten sich die Speedfires für das Finale in Berlin.

Ausnahmsweise mal einigermaßen gemütlich gestaltete sich die 600km Hinfahrt nach Berlin. Schon Samstag Nachmittag konnten sich Vivien, Sandra, Sebastian und Paul ins Auto packen, da Roy (der von der Arbeit aus sonst erst in der Nacht hätte fahren können) sich freundlicherweise bereit erklärt hat Sonntag früh per Flugzeug nachzukommen.

Nach der gründlichen Vorbereitung auf die Spiele in diversen Berliner Lokalitäten trafen die Speedfires erstaunlich munter in der Halle ein. Die ersten Spiele waren dann allerdings auch gleich die schwierigsten (insbesondere da wir auf Anna als beste Dame verzichteten, die sich auf die deutschen Meisterschaften kommende Woche vorbereitete):

Paul traf auf den Berliner Sebastian Kloss. Der hatte sich nach den letzten sehr knappen Niederlagen eine neue Strategie zugelegt und gewann prompt und sicher in zwei Sätzen. Mehr Gegenwehr gelang unserer Sandra gegen die Geheimwaffe Franziska Ottrembka. Trotzdem reichte es für ein glattes 0:2 aus Poinger Sicht. Deutlich schwerer tat sich der Berliner Michael Neutzsch (aktuell Nr. 2 der Deutschen Rangliste) gegen unseren Sebastian der sehr konzentriert und laufstark den ‚Anschlusstreffer‘ landete. Leider musste sich Roy auf dem Nebenplatz nach einem sehr spannenden Spiel mit dem Routinier Andre Noll ganz knapp geschlagen geben. Mit den Doppeln bestand also nur noch die Hoffnung auf ein Unentschieden. Tatsächlich konnten Sandra und Paul ihr Mixed durchaus souverän gewinnen (wobei man sagen muss dass die Berliner ihrer Franziska eine Ruhepause gönnten). Es hing also an Sebastian und Roy die gegen zwei Berliner Sebastians (Kloss/Wolff-Marting) ran mussten. Die Zuschauer konnten ein starkes Dreisatzmatch sehen, leider mit einem knappen aber ungünstigen Ausgang für die Speedfires. Insgesamt also ein nicht unverdientes 2:4 für die Berliner Füchse.

Damit hieß es im Spiel um Platz 3 wieder einmal gegen Bautzen anzutreten. Der Klassiker Paul gegen Christian Matthes auf Platz eins wurde wie immer mit Spannung erwartet. Die letzten Duelle konnte Christian für sich entscheiden. Diesmal jedoch war Paul voll konzentriert, oft ein Tick schneller und sicherer im Spiel. 1:0 Führung für Poing. Im Nachbarfeld schlug Mannschaftsneuling Vivien gegen die erfahrene Cathleen Selge auf. Ein hervorragender erster Satz und schon hieß es 16:12. Im zweiten Satz dann ebenso tolle Ballwechsel leider mit dem umgekehrten Ergebnis 12:16. Im dritten Satz siegen dann die Nervosität und die Bautzenerin knapp wieder mit 16:12. Schade aber ein toller erster Auftritt! Weiter ging es mit Sebastian gegen den starken Stephan Weise. Ein krasses Hin- und Her, sowohl mit dem Speeder als auch mit der Führung. Nach 16:9 und 11:16 musste auch hier der dritte Satz entscheiden. Sebastian behielt die Nerven und gewann stark mit 16:8. Also 2:2 nach den Einzeln. Leider war das Mixed Vivien/Paul gegen die gut eingespielten Selge/Matthes eine sehr eindeutige Sache, was, wie man klar sagen muss, nicht an der Dame im Feld lag. Der Druck lag also wieder auf den Herren, ein Zweisatzsieg musste her um die Chancen zu wahren. Die Bautzener hatten sich hier sehr stark aufgestellt (Stephan Weise / Michael August). Trotzdem gelang es Roy/Sebastian den ersten Satz fantastisch mit 16:11 zu gewinnen. Der zweite war dann um so umkämpfter und ging etwas ärgerlich mit 14:16 an die Bautzener. Damit stand die Niederlage bereits fest und die Luft war raus. Auch hier also wieder ein knappes aber ebenso nicht unverdientes 2:4.

Damit insgesamt Platz 4 für die Poing Speedfires, ein Auftritt in diesem ersten DCV Mannschaftspokal der sich trotz aller größeren Hoffnung sehen lassen kann!

Anna bei den Damen und Sandra bei den Damen Ü35 holen die Deutsche Meisterschaft 2017 zu den Poing Speedfires!

Einfach Wahnsinn! Wie kann man besser dieses Erfolgserlebnis beschreiben: 2 Spielerinnen fahren nach Wolfsburg zu den DCV Deutschen Einzelmeisterschaften im Crossminton. Und beide kommen als Deutsche Meisterin nach Hause. Anna bei den Damen und Sandra bei den Damen Ü35. Fast unglaublich!

In der Damen Ü35 Kategorie haben sich dieses Jahr nur vier Spielerinnen nach Wolfsburg zu den Meisterschaften getraut. Als eines der ersten Spiele hat es Sandra mit der für Berlin spielenden Stuttgarterin Miri Rado (Speedminton® Gekkos Berlin e.V.) zu tun. Nach einer Anlaufphase (8:16) holt Sandra auf und schafft das rettende 17:15. Als auch der dritte Satz 16:11 ausgeht ist die Erleichterung schon mal groß. Gegen Constanze Lorang (ebenso Berlin) klappt alles von Anfang an besser, trotzdem bleibt es immer eng aber mit dem besseren Ausgang und einem schönen 2:0 Sieg für Sandra. Im letzten Spiel kann sie locker aufspielen. Stets konzentriert und laufstark spielt sie gegen Steffi Przykalla von den Neissespeedern 09 Görlitz. Insbesondere der erste Satz ist eine klare Sache und auch der zweite geht mit 16:13 an unsere Spielerin. In diesem Jeder-gegen-Jeder Modus bedeuten damit drei Siege den Gesamtsieg und die Ehrung zur Deutschen Meisterin Damen Ü35!

Währenddessen kämpft sich Anna durch ihre Gruppe gegen einen Mix aus starken Spielerinnen: Jessica Frömter (Görlitz), Mira Schirdewan (WobSpeeders) und Patricia Legendarski (Elbspeeders eV), die spätere Bronzemedalliengewinnerin). Gewohnt konzentriert und stark erspielt sie sich einen Satz nach dem anderen und geht ohne Satzverlust als Gruppenerste ins Viertelfinale. Dort bekommen sie und ihre vermutlich stärkste Gegnerin, die Berliner Füchsin Franziska Ottrembka ein Freilos und dürfen so gleich ins Halbfinale. Während sich Franziska gegen eine ganz stark spielende Patricia über drei Sätze kämpfen muss schafft Anna einen 2:0 Sieg gegen Steffi Weiß. Diese hatte sich vorher gegen Andrea Horn durchgesetzt, die damit zum ersten Mal seit 2012 nicht unter die Top 3 bei den Deutschen Einzelmeisterschaften kommt.

So kommt es also am Sonntag Nachmittag zu dem nicht ganz unerwarteten Finale Anna gegen Franziska Ottrembka. Ebenso erwartet das für beide Seiten anstrengende und ausgeglichene Spiel. Von Anfang an versucht Anna mehr Druck zu machen, muss sich aber über mehr unforced errors ärgern und verliert knapp den ersten Satz mit 15:17. Es wäre aber nicht Anna, wenn Sie sich nicht entsprechend steigern könnte. Weiter macht sie Druck, erwischt gekonnt die Konter von Franziska und schafft ein relativ klaren 16:10 Sieg im zweiten Satz. Natürlich muss der dritte Satz entscheiden. Weiter geht es hin und her, Franziska stellt mehrfach ihr Spiel um, von aggressiv zu abwartend, von schnell zu hoch. Anna bleibt gewohnt ruhig (von ein paar unnötigen Fehlern einmal abgesehen, die aber nicht spielentscheidend sind). Anna geht und bleibt stetig in Führung und holt sich mit ein paar fantastischen Rückhand-Winnern mehrere Matchbälle. Trotzdem bleibt es spannend und Franziska kommt noch einmal heran bis der Druck zu hoch wird und ein Abwehrschlag leicht ins Seitenaus geht. 16:13 für Anna und damit nach der Deutschen Meisterschaft 2016 auch Deutsche Meisterin 2017!

Nicht ganz unerwähnt sollte bleiben dass unser Charly (der allerdings weiter für seine Fürsty Speeders spielt) in der Kategorie Herren Ü50 ebenso ins Finale kommt und seinen Titel von 2016 nur ganz knapp nicht verteidigen konnte. Gratuliere!

Poinger Crossminton-Spieler holen Silber und Bronze

Von Anfang bis Ende der Wahnsinn: Die ICO Crossminton World Championships 2017 in Warschau!

8 Speedfires machen sich auf den Weg nach Polen um DAS Event der Crossmintonszene hautnah miterleben zu dürfen. Und natürlich nicht nur als Zuschauer sondern um die weltbesten Spieler tüchtig herauszufordern.

Bilanz im Doppel: Treppchenplatz für das Damendoppel Ü35, Platz 17 und 33 fuer die Herrendoppel, Platz 9 in der Kategorie Herren Ü50, und Vizeweltmeisterin Damendoppel Anna Hubert

Während Christian, Charly, Anna und Sebastian sich gemütlich in Ihre jeweiligen Flieger setzen, sich irgendwie durch die Unwetter in Polen durchschlängeln konnten und pünktlich zur Eröffnungsfeier in der Tennisanlage „Warszawianka“ sein konnten, musste Vivien, Sandra, Roy und Paul einiges durchmachen: statt um 19:20 Uhr los zu fliegen, saßen wir im ersten Flugzeug 2 Stunden fest und konnten dann wegen Bremsproblemen nicht starten; das zweite Flugzeug war zwar bald am Start und in Ordnung, aber es war trotzdem schon zu spät. Also hieß es um 1 Uhr früh wieder nach Hause zu fahren und den nächstbesten Flug am kommenden Tag um 11 Uhr zu nehmen. Eng, wenn man bedenkt, dass die ersten Spiele um 12 Uhr anfangen sollten. Glücklicherweise war das erste Spiel der Speedfires erst um 14 Uhr angesetzt. Perfektes Timing also. Hätte man denken können. Dazwischen kamen allerdings einige Unwetter weswegen wir nicht landen sondern 45 Minuten kreiseln durften und dabei so gehörig durchgeschüttelt wurden dass es den ganzen Tag brauchte bis alles grün wieder aus den Gesichtern verschwunden war. Die entwurzelten Bäume, die nur knapp an einer der Halle vorbei gefallen sind und die schwüle Hitze in den Hallen machten den Anfang nicht gerade einfacher.

Doppel

All dem zum Trotz konnte die erste Doppelbegegnung der Speedfires gespielt werden, was vor allem daran lag, dass auf beiden Seiten Poinger standen. Dummerweise hat die Auslosung nämlich Roy Gralke, der mit Markus Blana (SpeedHenne(f) Happerschoß) spielte, gegen die eingespielten Vereinskollegen Sebastian Bruszies und Paul Holleis spielen lassen. Letztere konnten, vermutlich hauptsächlich da Sebastian einigermaßen ausgeruht das Spiel in die Hand nehmen konnte, gewinnen. Danach war allerdings, wie in den letzten drei Turnieren ebenfalls, Schluss gegen Sönke Kaatz und Robin Joop (Buxtehude / Wolfsburg). Wieder knapp, aber wieder kein Satzgewinn, was aber nicht so dramatisch ist, insbesondere da die beiden dann später am Tag auch Doppelweltmeister wurden. Am Ende Platz 33 für Roy und Platz 17 für Sebastian/Paul.

In der Kategorie Herren Doppel Ü50 lief es für Christian Enzinger mit Partner Roland Kögl (Speedlights München) etwas besser. Sie belegten nach dem Aus im Achtelfinale und ihrem ersten gemeinsamen Turnierauftritt Rang 9. Charly Knobling, spielt eigentlich bei den Fürsty Speeders in Fürstenfeldbruck, ist aber trotzdem Mitglied bei den Poingern, erreichte mit seinem Partner Michael von Lennep (Speed Lions Düsseldorf) Platz 17.

Und was machen die Damen? War manchmal gar nicht so einfach den Überblick zu behalten, auf diesem doch sehr weitläufigen Gelände mit unzähligen Tennisplätzen und unterschiedlichem Belag.

Trotz einer relativ kleinen Gruppe und großen Erwartungen in der Kategorie Damendoppel Ü35 dürfen sich Vivien Klee und Sandra Hesse über die Bronzemedaille freuen, sehr starker Auftritt!

Bereits gespielt hatte da Anna Hubert mit ihrer Berliner Spielpartnerin Franziska Ottrembka. Obwohl die beiden bis dahin immer nur gegeneinander gespielt hatten, finden sie sehr schnell zusammen und gewinnen ein spektakuläres KO-Spiel nach dem nächsten und stehen völlig zu Recht im Finale. Dort müssen sie sich in einem spannenden Match den beiden Damen (Krisztina Bognar / Ágnes Darnyik) aus Ungarn u.a. mit 19:21 geschlagen geben. Tolles Turnier von Ágnes, die dann auch noch im Einzel Weltmeisterin wurde. Aber ein großartige Leistung von unserer Anna und ein verdienter 2. Platz: Vizeweltmeisterin im Damendoppel!!!

Acht Speedfires – vier Kategorien. Wieder viele hart umkämpfte Spiele. Am erfolgreichsten, wie so oft, Anna als Trizemeisterin; Paul und Sebastian schaffen es ins Sechzehnteltelfinale und Vivien rauscht vor auf Platz 5!

Einzel

Bei den Herren Ü50 ist es besonders eng. Christian Enzinger tritt in seinem ersten außerpoingschen Turnier in einer 5er Gruppe gegen einige recht erfahrene Leute an. Am Ende haben er und zwei andere jeweils 3 Spiele gewonnen und die jeweiligen Sätze müssen ausgezählt werden. Dabei reicht es für ihn ganz knapp und sehr ärgerlich nicht und scheidet leider aus. Als Gruppendritter laesst er aber trotzdem einige hinter sich (zB den Stuttgarter Mixed Ü50 Weltmeister Uwe Schraub) und belegt Platz 19!

Charly Knobling gewann ebenso drei Spiele in seiner 5er Gruppe, kam als Gruppenzweiter aber weiter (und verwies damit den Munich Speedlight Roland Kögl auf den dritten platz der Gruppe). Das nächste Spiel gewinnt er souverän, verliert aber ebenso klar gegen, wie eigentlich immer, Bogdan Miezynski im Achtelfinale.

In der größten, der Herrenkategorie (Open), starten Paul, Sebastian und Roy mit 107 anderen Spielern.

Roy Gralke erwischt eine schwere Gruppe und kann nur im ersten Satz gegen den Weltranglistendritten Dasen Jardas mithalten. Leider kommt er auch in den anderen Spielen nicht an seine eigentliche Leistung ran und verliert auch das dritte Spiel denkbar knapp mit 16:7, 15:17, 14:16 gegen den Nürnberger Knightspeeder Thomas Dirr, es bleibt Rang 82.

Sebastian Bruszies geht an Nummer zwei gesetzt in die 4er Gruppe. Der erste Gegner ist schnell besiegt, als nächstes steht aber der junge Münsteraner Tom Meyer gegenüber. Nach dem ersten Satzverlust kommt er wieder besser ins Spiel und kämpft sich zäh und geduldig zum Dreisatzsieg. Nun wartet noch der erfahrene Rene Lewicki auf ihn, der nur zwei schnelle Sätze gegen Tom gebraucht hatte. Sebastian behält die Nerven und stets die Oberhand, mit 16:9 und 16:10 Gruppenerster. Stark!

In der KO-Runde kommt er per Freilos gleich ins 16tel Finale, trifft dort allerdings auf den auf Platz 13 der Weltrangliste stehenden Tomasz Kaczmarek. Wieder einmal sieht man, dass wir zu selten die Gelegenheit haben mit solchen Leuten zu trainieren und Sebastian kann zwar einige Punkte holen aber dessen Sieg nicht richtig gefährden.

Paul Holleis darf als erstes gegen den Franzosen Damien Guillemineau ran. Von der Ranglistenplatzierung her eigentlich eine klare Sache, trotzdem geht der erste Satz nur ganz knapp mit 16:14 an Paul. Im zweiten Satz wundern sich manche neu dazugekommenen Zuschauer, dass es nach einer halben Stunde immer noch erst 2:2 steht. Allerdings hatte hier die Zähltafel nicht ausgereicht, die nur bis 25 ging. Nach endlosem Hin- und Her holt sich der Franzose den Satz am Ende mit 29-27, vermutlich das höchste Ergebnis der WM. Auf noch so einen Satz lässt sich Paul aber nicht ein und gewinnt den dritten stark mit 16:7. Nach einem schnellen Sieg gegen den Polen Jozef Puskas, heißt es dennoch alles oder nichts im letzten Spiel gegen „Kuwi“ Christoph Kuwert-Behrenz aus Berlin: Bei 0:2 raus, bei 2:1 oder besser Gruppenerster! Natürlich verliert Paul den ersten knapp mit 17:19, kann dann aber aufdrehen und erspielt sich sicher das erhoffte 2:1.

In der KO-Runde der besten 64 trifft er auf den Norweger Stian Pasche. Wie gewohnt versiebt er den ersten Satz, kann sich aber dann doch noch zusammenreißen, seine Fehlerquote etwas reduzieren, und nach Kraftakt noch gewinnen. Im 16tel Finale trifft er dann wie schon so oft auf den Kölner Boubacar Diallo. Diesmal noch deutlicher wie sonst verliert er, leicht verwirrt von der schlechten Leistung, glatt in zwei Sätzen. Ärgerlich, aber insgesamt trotzdem mit dem 17. Platz die Erwartungen sehr gut erfüllt.

Bei den Damen Ü35 gelingt Vivien Klee gleich ein Paukenschlag in dem sie als ungesetzte gegen die an Nummer 4 gesetzte Tatjana Zrnic gewinnt. Danach noch ein Gewinn und sie kommt trotz eines knappes Dreisatzverlustes im dritten Spiel als Gruppenerste weiter. Mit Hilfe eines Freiloses kommt sie damit direkt ins Viertelfinale. Dort ist zwar relativ schnell gegen die spaetere Vizeweltmeisterin Magdalena Lelonek Schluss, aber das lag auch viel daran, dass sie oft mehr mit sich als gegen ihre Gegnerin zu kämpfen hatte. Platz 5 auf jeden Fall mehr als verdient!

Sandra Hesse spielt sich über mehrere spannende Dreisatzmatches (inklusive gegen Weltranglistenzweite Dorota Lewandowska) als Gruppenzweite in die KO-Runde. Dort kämpft sie sehr laufstark um jeden Punkt, muss aber dann doch mit 11:16, 14:16 die Segel streichen. Trotzdem kann man mit einem Top 10 Platz bei den Weltmeisterschaften mehr als zufrieden sein!

Last but not least – das Beste, besser gesagt, die Beste zum Schluss. Anna Hubert zeigt wieder einmal mehr, dass sie eine weltklasse Spielerin ist. Aktuell auf Ranglistenplatz 7, gewinnt sie alle ihre Vorrundenspiele und gibt bis zum Halbfinale nur einen einzigen Satz ab! Dann steht sie der besten ungarischen Spielerin Ágnes Darnyik gegenüber, die ja tags zuvor bereits Doppelweltmeisterin wurde. Den immer lauter werdenden ungarischen Fans und der stark spielenden Ágnes hielt sie lange stand, gewinnt den zweiten Satz mit 16:12, muss sich dann aber doch knapp im dritten Satz geschlagen geben. Eine unglaublich stark verdiente Bronzemedaille für ihre super Leistung, wer (außer alle anderen) hätte noch vor zwei Jahren das für möglich gehalten. Damit Silber im Doppel und Bronze im Einzel bei den Crossminton Weltmeisterschaften 2017! Einfach Spitzenmäßig, da wird sich was tun an der Weltrangliste!

Vielen Dank an Crossminton Polska, selten erlebt, dass ein Zeitplan so gut eingehalten werden konnte!

Vom Silber in Schweden bis zum verdienten Gold in Norwegen

Von wegen Semesterpause und Langeweile. Zwei große internationale Turniere in 10 Tagen! Als einzige Spielerin für die Poing Speed Fires brachte Anna Hubert die Poinger Spielfreude hoooch in den Norden. Zuerst ging es nach Schweden zu den Swedish Open in Göteborg.

Mit ihrem Mixed-Partner, Sebastian Christoph (von den Nürnberger Knightspeeders), schaffte sie es bis ins Viertelfinale. Doch der große Schlagabtausch sollte sich in der Damenkategorie abspielen. Schon in der Gruppenphase wurde klar, dass die Schweden nicht zu unterschätzen waren. Ohne Satzverlust marschierte Anna trotzdem durch bis ins Finale. Doch in diesem war alles geboten. Flach und schnell! Hoch und langsam! Präzision und Leichtsinn! Eine Wahnsinns-Kondition auf beiden Seiten – und das über 3 endlos scheinende Sätze – bei denen am Ende die Schwedin Linnea Granberg das Glück auf ihrer Seite hatte.

Aber! Ein fantastischer zweiter Platz, eine Silbermedaille und die Herausforderung auf Revanche eine Woche drauf bei den Norwegian Open in Oslo.

Nach ein paar Tagen Erholung und etwas Sightseeing hieß es dann endlich wieder: „Go Anna Go“. Wieder mit Sebastian Christoph schied sie, nur denkbar knapp im dritten Satz, im Viertelfinale gegen Sönke Kaatz (Buxtehude) mit Partner Adrian Lutz (Münster), aus und belegte so auch wieder den 5. Rang.

In der Gruppenphase der Damenkategorie, hatte sie dann ihre Möglichkeit auf Revanche, nach der Niederlage in Göteborg, genutzt und die Schwedin Linnea Granberg – natürlich auch wieder in einem spannenden Dreisatzmatch – geschlagen. Doch das sollte nicht das einzige Aufeinandertreffen der beiden an diesem Tag werden. Beide schafften es auf unterschiedlichen Wegen ins Finale, welches schon im Vorfeld auf ein abwechslungsreiches Spiel hindeuten sollte. Und so war es auch. Ein spektakulärer Schlagabtausch – so wie in Schweden – wurde den Zuschauern geboten!! Aber dieses Mal mit dem schöneren Ausgang für Anna Hubert.

Die verdiente Goldmedaille!!!

Nicht unerwähnt bleiben sollte allerdings auch der erfolgreiche Auftritt unseres Charly Knobling, der, für seinen Fürstenfeldbrucker Verein auftretend, ebenso beide Turniere bestritt und einen 2. Platz im Mixed bei den Norwegian Open erreichen konnte!

Poinger Crossminton-Spieler feiern erfolgreichen Sommer

Ganz viel ist passiert in den letzten Wochen: die Summer-Edition des Munich Cup, das ausgebuchte Schnuppertraining im Poinger Ferienprogramm und die German Open in Fürstenfeldbruck – alles eine gute Vorbereitung auf die beiden Turnier die wir selbst ausrichten (21./22. Oktober)!

Während Anna Hubert erfolgreich in Skandinavien unterwegs war (wir berichteten), fand die Siegerehrung des, zum ersten Mal ausgerichteten, Munich Cup Summer, welcher über drei Monate ausgespielt wurde, statt. Und auch hier waren die Poinger sehr gut vertreten. Alexander Mrosack wurde in seiner sehr guten Leistung bestätigt und belegte den 3. Platz. Gefolgt von Roy Gralke auf Rang 5. Sandra Hesse, als beste Dame im Feld, auf Platz 8 und Christian Enzinger auf Rang 10. Aber turniertechnisch sollte es noch nicht zu Ende sein.

Munich Cup Summer 2017 – Ein Klick führt zur Bildergalerie

In der Zwischenzeit geht der Sommer langsam zu Neige und Crossminton kann man ja, wie ihr wisst, überall und zu jeder Zeit spielen. Bei fantastischem Spätsommerwetter veranstalteten die SpeedFires draußen, im Sportzentrum Poing, ein Schnuppertraining (Poinger Ferienprogramm). Eigentlich nur für Kids, ab 8 Jahren, und Jugendliche gedacht, war die Neugier der jüngeren Geschwister und auch der Eltern so groß, was diese veranlasste, dazubleiben um diesen abwechslungsreichen Sport selbst einmal auszuprobieren. Alles in allem war dies eine absolut gelungene Aktion und es sind sogar ein paar kleine und auch große Crossmintontalente bis heute geblieben.

Crossminton Schnuppern – Ein Klick führt zur Bildergalerie

Der Höhepunkt des Sommers aber waren die German Open. Das größte internationale Turnier in Deutschland, welches dieses Jahr in Fürstenfeldbruck stattfand. Knapp 200 Teilnehmer lieferten sich, auf drei Turnhallen verteilt, in Einzel- und Doppelkategorien, viele spektakuläre Spiele.

Dabei waren: Marie Schubert (5. Platz/ U14), Katrin Huber (5. Platz/ U18), Sabrina Gross (13. Platz/ Damen), Sandra Hesse (7. Platz/ Damen Ü35), Paul Holleis (23. Platz/ Herren), Sebastian Bruszies (23. Platz/ Herren), Alexander Mrosack (23. Platz/ Herren), Roy Gralke (34.Platz/ Herren), Christian Enzinger (Platz 9/ Herren Ü50). Doch den wohl sportlich schönsten Erfolg, aus Poinger Sicht, erzielte Vivien Klee. Eine weitere, stark, aufstrebende Spielerin der SpeedFires. Sie belegte den 3. Platz bei den Damen Ü35. Und auch Anna Hubert holte sich die Medaille für den 3. Platz, in ihrer Altersklasse, ab.

Die Ergebnisse der Doppelkategorien: Mix-Doppel > Katrin Huber mit Partner Matej (9.), Anna Hubert mit Partner Frederik Stokke Killingberg (9.), Sandra Hesse mit Partner Christian Enzinger (9.). Herren-Doppel > Roy Gralke mit Partner Alexander Mrosack (5.), Paul Holleis mit Partner Sebastian Bruszies (5.)

Und nicht zu vergessen… als halber Poinger und Veranstalter der German Open: Charly Knobling erreichte den 2. Platz bei den Herren Ü50.

German Open 2017 – Ein Klick führt zur Bildergalerie

Nach so einem aufregenden Sommer wird es Zeit…. Zeit für DAS Poinger Crossminton-Event! Am 21. und 22. Oktober werden die Speeder wieder durch die Poinger Sporthalle pfeifen. Ein Wochenende – Zwei Turniere. Alle weiteren Details im nächsten Bericht.

Ein Wochenende ~ Zwei spannende Crossminton Turniere

Es ist wieder soweit. Der internationale Crossminton Verband (ICO), der deutsche Crossminton Verband (DCV) und natürlich die Crossminton-Spieler des TSV Poing e.V. (Poing SpeedFires) veranstalten am 21. & 22. Oktober das weltweit einzige Crossminton-Event, bei welchen in drei Kategorien gestartet werden darf.

Ausschlaggebend dafür, ist die Konstellation. Zum einen die „Deutsche Doppelmeisterschaft“ (Damendoppel, Herrendoppel, Mixdoppel = zwei Kategorien spielbar) auf rein nationaler Ebene. Und zum Zweiten: die „3. Poing Open“, als reines Einzelturnier (nur eine Kategorie möglich), auf internationaler Ebene.

In beiden Turnieren werden wir dieses Jahr wieder die Chance haben, die Elite des Crossminton Sports zu sehen.

Vom amtierenden Welt- und Europameister bis hin zum Deutschen Meister/in aus den verschiedenen Einzel- und Doppelkategorien wird vertreten sein, was auf spannende und abwechslungsreiche Spiele hoffen lässt.

Da die Teilnehmerzahl schon jetzt – vor Anmeldeschluss! – über den Erwartungen liegen, wird dieses Megaturnierwochenende, am Samstag, den 21.10.2016, schon um 7:00 Uhr eröffnet.

Gestartet wird 7:30 Uhr mit der „Deutschen Doppelmeisterschaft“. Im Anschluss, besser gesagt ab dem späten Nachmittag, und eigentlich parallel zu den noch laufenden Doppelspielen, beginnt die Poing Open mit den Einzelwettkämpfen (Damen, Herren und Herren Ü40), welche sich dann bis in die späten Abendstunden erstrecken und am Sonntag fortgesetzt wird.

Am Sonntag, den 22.10.2016, wird ab 7:30 Uhr mit den Kids U14 und auch allen anderen Kategorien (Damen, Herren, Herren Ü40) gleichzeitig gestartet und am späten Nachmittag/ frühen Abend beendet.

Die Siegerehrungen von beiden Veranstaltungen werden abhängig vom Turnierverlauf durchgeführt.

Einen ganz lieben Dank an dieser Stelle an unseren Sponsor Herr Mettin (Allianz Generalvertretung, Poststrasse 19, 85586 Poing), sowie an alle fleißigen Helfer, die uns an diesen Tagen unterstützen werden.

Wer also dieses klasse Crossminton-Event nicht verpassen möchte, ist ganz herzlich eingeladen, vorbeizuschauen und die Spieler kräftig anzufeuern.

Bei hausgemachten Kuchen und anderen kleinen Schmankerln können alle anfeuerungsgeschwächten Gäste dann natürlich wieder zu Kräften kommen.

Wir freuen uns schon auf Euch

Eure Poing Speed Fires

Poinger Crossminton-Spieler holen dreimal Gold beim Crossminton-Marathon-Wochenende

Was für eine Mammutaufgabe. Nicht nur für die Veranstalter, Ausrichter und Organisatoren, welche auch im laufenden Spielbetrieb teilgenommen hatten, sondern auch für das breitgefächerte Teilnehmerfeld. Das Mega-Crossminton-Wochenende (wir berichteten) ist geschafft.

Hier zwei fantastische Zeitungsartikel von Olaf Heid, Sportberichterstatter der Ebersberger Zeitung

crossminton-ez-25-10-2017

crossminton-ez-09-11-2017

Aber bis es soweit war, hieß es, ein spannendes Match nach dem nächsten – besser gesagt teilweise nebeneinander – im Auge zubehalten, anzufeuern und mitzufiebern. Viele nervenaufreibende Ballwechsel ließen die Zuschauer den Atem stocken.

Spieler, die in allen drei Kategorien angetreten waren, bestritten mindestens 11 Vorrundenspiele. Und Spieler die dann noch über mehrere KO-Runden das Finale erreicht hatten, erkämpften sich dies in mehr als 20 Spielen!!!

„Hut ab!“, all denjenigen, die sich dieser Herausforderung gestellt hatten! Und Gratulation allen Siegern und Medaillengewinnern!

Für Poing angetreten waren:

-Samuel Holleis (Poing Open 2. Platz bei den Jungs U12)

-Florian Sachs (Poing Open 3. Platz bei den Jungs U14)

-Marlene Stoecker (Poing Open 2. Platz bei den Mädels U14)

-Lea Schalla (Poing Open 3. Platz bei den Mädels U14)

-Marina Fleiss (Poing Open 4. Platz bei den Mädels U14)

-Charly Knobling (Poing Open 3. Platz bei den Herren O40 / Dt. Doppelmeisterschaft 5. Platz Herrendoppel + 7. Platz Mixed)

-Hugo Escudero-Gonzalez (Poing Open 5. Platz bei den Herren O40)

-Christian Enzinger (Poing Open 7. Platz beid en Herren O40 / Dt. Doppelmeisterschaft 5. Platz –Herrendoppel + 10. Platz Mixed)

-Manfred Welschak (Poing Open 10. Platz bei den Herren O40 / Dt. Doppelmeisterschaft 10. Platz Herrendoppel + 10. Platz Mixed)

-Vivien Klee (Poing Open 7. Platz bei den Damen / Dt. Doppelmeisterschaft 5. Platz Damendoppel + 5. Platz Mixed)

-Katrin Huber (Poing Open 10. Platz bei den Damen / Dt. Doppelmeisterschaft 7. Platz Damendoppel + 7. Platz Mixed)

-Sandra Hesse (Poing Open 10. Platz bei den Damen / Dt. Doppelmeisterschaft 5. Platz Damendoppel + 10. Platz Mixed)

-Sabrina Gross (Dt. Doppelmeisterschaft 5. Platz Damendoppel + 10. Platz Mixed)

-Sebastian Bruszies (Poing Open 5. Platz bei den Herren / Dt. Doppelmeisterschaft 3. Platz Herrendoppel + 5. Platz Mixed)

-Paul Holleis (Poing Open 5. Platz bei den Herren / Dt. Doppelmeisterschaft, 3. Platz Herrendoppel)

-Alexander Mrosack (Poing Open 9. Platz bei den Herren)

-Roy Gralke (Poing Open 13. Platz bei den Herren / Dt. Doppelmeisterschaft 5. Platz Herrendoppel + 7. –Platz Mixed)

-Oliver Gross (Dt. Doppelmeisterschaft 10. Platz Herrendoppel)

Das „Perfekte Triple“ in ihrer Altersklasse (U14) gelang Marie Schubert. Sie schaffte es zum dritten Mal in Folge, ihren Titel bei der Poing Open zu verteidigen und belegte zusätzlich den 10. Platz bei der Dt. Doppelmeisterschaft im Mixdoppel. Ihren Spitznamen „Goldmarie“ trägt sie somit zu Recht.

Ja und was ist mit Anna Hubert??? Eine ausgezeichnete Spitzensportlerin verdient es, als krönenden Abschluss dieses Wochenendes, zum Schluss genannt zu werden. Anna Hubert holt bei den Dt. Doppelmeisterschaften mit ihrer Partnerin Jana Nabel (Wolfsburg) den 1. Platz im Damendoppel und mit ihrem Partner Sönke Kaatz (Buxtehude) den 1. Platz im Mixed. Bei den „3. Poing Open“ verliert sie zwar knapp das entscheidende Finale, aber gewinnt eine Silbermedaille, die wie eine „Goldene“ glänzt.

Vielen, vielen Dank allen fleißigen Helfern und Teilnehmern! Ohne Euch hätten wir dieses Event nicht meistern können.

4 Poinger Crossminton Spieler räumen in einer Nacht 8 Medaillen aber allen voran Doktor Paul Holleis

Rekord! 23 Stunden unterwegs und 8 Urkunden eingeheimst! Die Red Devils Bautzen um Christian Matthes,Torsten Köhler, Cathleen Selge und ganz vielen anderen haben es mal wieder geschafft ein rundum gelungenes Turnier mitten in die Nacht zu legen.

Ergebnisse ganz subjektiv:

Charly Knobling (Mitglied im TSV Poing, spielt aber für Fürstenfeldbruck) marschierte als Gruppenzweiter, der Herren Ü40, bis ins Finale und gewann dieses dann auch noch mit super Ballwechseln und einer unglaublichen Kondition.

Alexander Mrosack, nach den 6 Stunden Fahrt doch noch halbwegs ausgeschlafen, zeigte wieder einmal, dass mit ihm immer zu rechnen ist. Alexander wurde von Sebastian Bruszies nur kurz aufgehalten, spielte sich aber über die Lucky Looser Runde zurück bis ins Viertelfinale. Genauso wie Paul Holleis und Sebastian Bruszies. Dass alle drei SpeedFires dann noch (mit Jonas Jönk von den WobSpeeders) das Halbfinale erreichten – ein Traum! Spannender kann ein Halbfinale nicht werden.

In der Ersten Partie hieß es für Alexander Mrosack, Zähne zeigen, aber gegen den stark spielenden Jonas hatte er am Ende doch keine Chance. Verlor zwar das Spiel, aber gewann eine Bronzemedaille, die sich sehen lassen kann.

Im Zweiten Halbfinale, wie sollte es anders sein, trafen die beiden Vereinskollegen Paul Holleis und Sebastian Bruszies aufeinander. Diese Partie war hoch anspruchsvoll, welche am Ende Paul für sich entscheiden konnte.

Finale Jonas Jönk – Paul Holleis: Schön anzusehendes Duell auf niedrigem Niveau (nur an der Ballhöhe über dem Boden gemessen!); das 2:0 aus Pauls Sicht brachte zwar das knappe Ergebnis nicht wirklich rüber, aber dafür den Paul zum Quer-durch-die-Halle hüpfen!!!

Das Poinger Doppelfinale – um halb vier Uhr früh morgens!! – mit dem besseren Ausgang für Sebastian Bruszies mit Paul Holleis gegen Alexander Mrosack mit Charly Knobling brachte noch das I-Tüpfelchen für einen verrückten „Tag“ und alle um 10 Uhr früh quasi gesund wieder nach Hause, der ganz normale Speedfires-Wahnsinn! eben…

Feiner Artikel :)) Ebersberger Zeitung / Merkur 12.02.2018 Redakteur Olaf Heid

BerichtEBESportlehrehrung2018

Daaankeschön :)

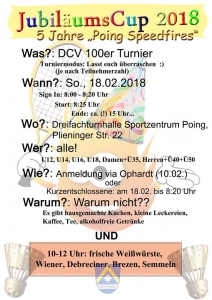

Crossminton – PoingSpeedFires – JubilämsplakatFacebook

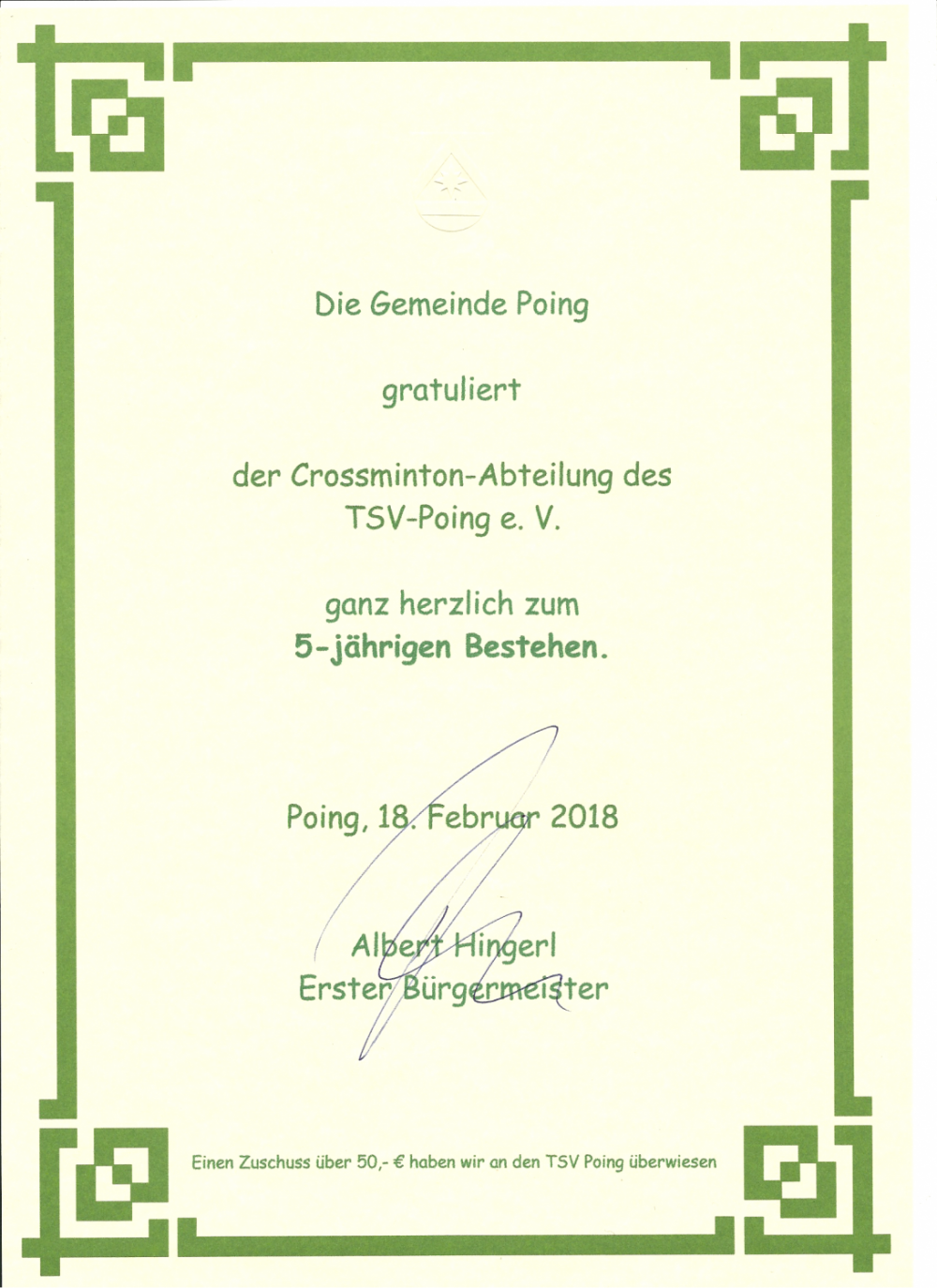

EhrenurkundeJubiläumCrossminton

Mit Spaß am Spiel zum Ziel

Ausgelassene Stimmung und spannende Ballwechsel beim Jubiläums Cup

Wir, die Poing SpeedFires, hatten geladen und 44 Teilnehmer, aus ganz Deutschland, sind dem Aufruf gefolgt. Natürlich waren auch einige Gäste, Zuschauer und die fleißigen Helfer vor Ort. Aber warum soviel schreiben… Neugierig? ..

Wir bedanken uns bei:

unserem Bürgermeister Herrn Albert Hingerl, welcher schon mehrfach die Schirmherrschaft übernommen hatte; ganz vielen Gemeindemitarbeitern; dem TSV Poing mit Herrn Robert Rieger, Andi Haase und Horst Ludwig; allen Gründungsmitgliedern; Herrn Mettin; allen Sponsoren und Helfern jeglicher Art; allen Redakteuren und Fotografen und allen Ehefrauen/ Ehemännern die ihre Partner so oft entbehrt hatten

Ihr alle habt es erst möglich gemacht, dass sich Crossminton in Poing etablieren durfte.

Natürlich haben auch wir – mit crossartigen Erfolgen – unseren Teil dazu beigetragen.

Hier die Ergebnisse des Jubiläums Cups:

Herren Ü40

Jugend U16

Jugend U12

Damen

Open Division

Hier noch ein paar tolle Eindrücke

Deutschlands erste Dreifachturnhalle mit durchgehender, fester Crossminton-Hallenmarkierung

Wolfgang Probst wurde für seine fantastische Mithilfe im Hintergrund und seine langjährige Mitgliedschaft (Turnierleitung und alles was mit Lizenzen und Meldungen zu tun hat) und seine Arbeit für den DCV (Deutscher Crossminton Verband) mit einer Sonderehrung ausgezeichnet.

Genauso geehrt für seinen unglaublichen Einsatz, für die Poing SpeedFires, wurde Roy Gralke. Er ist einer der wenigen, der regelmäßig – eigentlich fast immer – im Training war. Flog „nur“ wegen eines Mannschaftsfinales, am Sonntag, Samstagnacht nach Berlin. Übernahm mehrfach die Mannschaftsführung, spielte innerhalb von 10 Tagen bei 5 Ligabegegnungen mit und zeigte Allen!, dass es sich lohnt dabei zu sein. Um nur ein paar von seinen grandiosen Verrücktheiten zu nennen.

Als einzige Dame im Herrenfeld, der Open Division, erspielte sich Anna Hubert beim JubiläumsCup einen unglaublichen 5. Platz. Was wiedereinmal ihre sportliche Stärke deutlich machte. In Sachen Schiedsen und Auszeichnungen den „Kleinen“ übergeben, bewies sie mannschaftsübergreifend ihre Klasse. Auch wenn es dieses Mal nicht für einen Treppchenplatz gereicht hatte.

Vielen Dank an unsere fleißigen Helfer

Auch wenn nicht mehr vollständig, es war ein super Jubiläumstag und wir freuen uns schon auf die nächsten crossartigen Jahre mit crossartigen Menschen!

„Rattenfänger“ von Hameln hat wieder zugeschlagen

Der Historische nur kurzzeitig und die Hamelner Jungs von Time Sports e.V. hatten mit Paul Holleis und Sebastian Bruszies auch kein einfaches Unterfangen…..

Die 1266km hatten sich für beide echt gelohnt. Paul H. und Sebastian B. erreichten beide, jeweils als Zweiter ihrer Gruppe, das Viertelfinale. Und in diesem war alles geboten. Ausgeglichene Ballwechsel auf hohem Spielniveau mit knappen Spielausgängen.

Die Begegnungen: Paul H. gegen Nico Franke (Time Sports) und Sebastian B. gegen Arne Kaufmann (Elbspeeders Hamburg). Während Sebastian bis ins Halbfinale durchmarschierte, scheiterte Paul am amtierenden U18 Weltmeister und aktuellen Nr. 1 der nationalen Rangliste. Welcher nun keine 18 mehr, aber noch stärker geworden war. Paul erreichte trotzdem einen fantastischen 5. Platz.

Doch ab diesem Zeitpunkt hieß es Daumen-Drücken für Sebastian. Im Halbfinale stand ihm der Kölner Bouba Diallo (KSBV Köln/ aktuell Platz 7 der nat. Rangliste) gegenüber. Sebastian kämpfte bis zum Schluss, musste sich aber am Ende, dem spielerisch überlegenen Bouba D., geschlagen geben. Aber!! Und nur das zählt!!

Sebastian Bruszies gewinnt Bronze!!! Open Division v.l.: Bouba Diallo (KSBV Köln), Nico Franke (Time Sports e.V.), Sebastian Bruszies (Poing SpeedFires), Maximillian Franke (Time Sports e.V.)

Und nicht nur die „Jungen“ hatten ihre super Leistungen auf´s Spielfeld gebracht. Auch dieser „Alte Hase“ hier zeigte, was in ihm steckt. Offiziell war Charly Knobling für die Fürsty Speeders angetreten. Doch auch als Mitglied der PoingSpeedFires ist sein Name einfach Programm. Dank Charly´s Entschlossenheit und einem ausgezeichneten „Killertraining“ bei uns, hatte er es zum wiederholten Male nach ganz oben auf´s Stockerl geschafft!!!

Herren Ü40 v.l.: Georges Nilos (SBC Shark Sport), Charly Knobling (Fürsty Speeders), Christian Barg (Elbspeeders Hamburg), Marcel van der Laan (Lightning Speeders, NED)

Ohne Punktverlust zum 3. Meistertitel

Was für eine Bundesligasaison. Zum ersten Mal in der Geschichte des Crossminton startete die Bundesliga um ein halbes Jahr versetzt erst letzten September und endete jetzt im März. Für unsere beiden Mannschaften eine grosse Herausforderung neben dem normalen Turnierbetrieb. Doch mit viel Einsatz und Unterstützung aus der 2. Mannschaft (Poing SpeedFires II) gelang unserer 1. Mannschaft (Poing SpeedFires I) der Super-Gau!!! ….

Absolute Entschlossenheit, Teamgeist und grandiose spielerischere Leistungen jedes Einzelnen waren das Rezept für diesen Erfolg.

Mit dabei waren: Anna Hubert, Roy Gralke, Sebastian Bruszies, Hugo Escudero, Paul Holleis und als „Der Neue im Bunde“ Alexander Mrosack.

Für alle sechs geht´s jetzt auf zum Bundesliga-Finalturnier – bei welchem nur die zwei besten jeder Liga (Nord, Ost, Süd und West) teilnehmen dürfen – nach….. BRÜHL